Separates 40-60% of solids, the bulk solids.

Our Products / Dissolved Air Flotation Anaconda

Separates 40-60% of solids, the bulk solids.

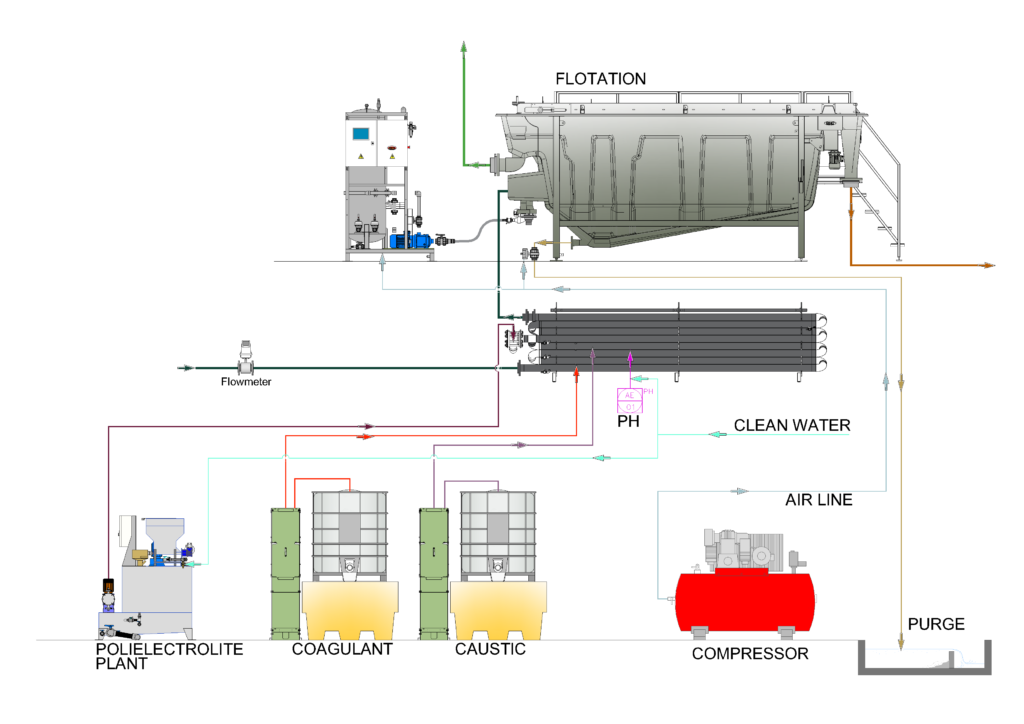

Certain chemical compounds are usually added to facilitate the flotation process. For the most part, these chemical reagents work in a way that creates a surface or structure that allows air bubbles to be easily absorbed or trapped. Inorganic chemical reagents, such as iron or aluminium salts and activated silica, are used to aggregate the solid particles so as to create a structure that facilitates the absorption of air bubbles.

Various organic polymers can also be used to modify the nature of the air-liquid or solid-liquid interfaces, or both. In general, these compounds act by positioning themselves at the interface to produce the desired changes.

The degree of clarification obtained when reagents are added to the wastewater depends on the amount of reagents used, and the care with which the processes are controlled and operated. By chemical precipitation it is possible to remove 80 to 90 per cent of suspended solids, 70 to 80 per cent of BOD5 and 80 to 90 per cent of bacteria. Comparable removal values for properly designed and operated primary sedimentation tanks without addition of reagents are between 50 and 70 per cent for suspended solids, 25 to 40 per cent for BOD5 and 25 to 75 per cent for bacteria.

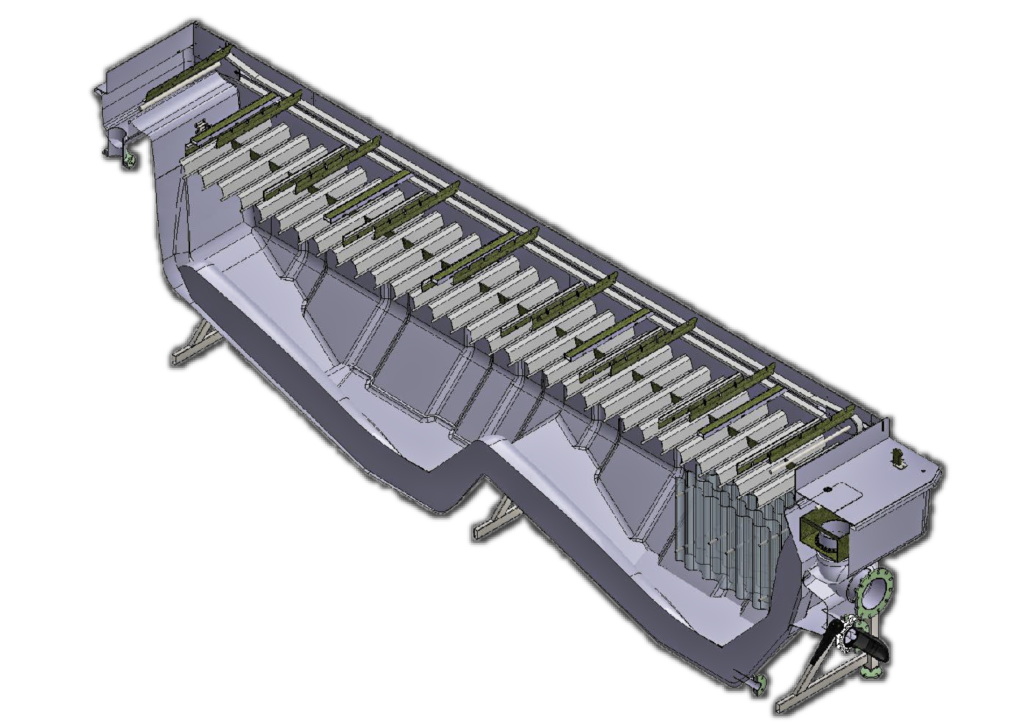

Our Anaconda® range of dissolved air floats is mainly made of glass fibre reinforced polyester (GRP), which gives it the ability to:

In our factory in Villavaquerín we manufacture different models of floats which, together with the different sizes of flocculators and pressurisation skid, allow us to adapt to the needs of the client depending on the flow and load of solids to be treated.

Consisting of a boiler, pumps, valves, supports and base in GRP, and structure in AISI 316.

By separating the skid from the DAF tank, we can better adapt to the needs of your project depending on the flow rate and the TSS to be treated, thus optimising the flotation process.

Allows in-line dosing of chemicals into the water. It consists of PVC, polypropylene, polyethylene or stainless steel pipes, depending on the application.

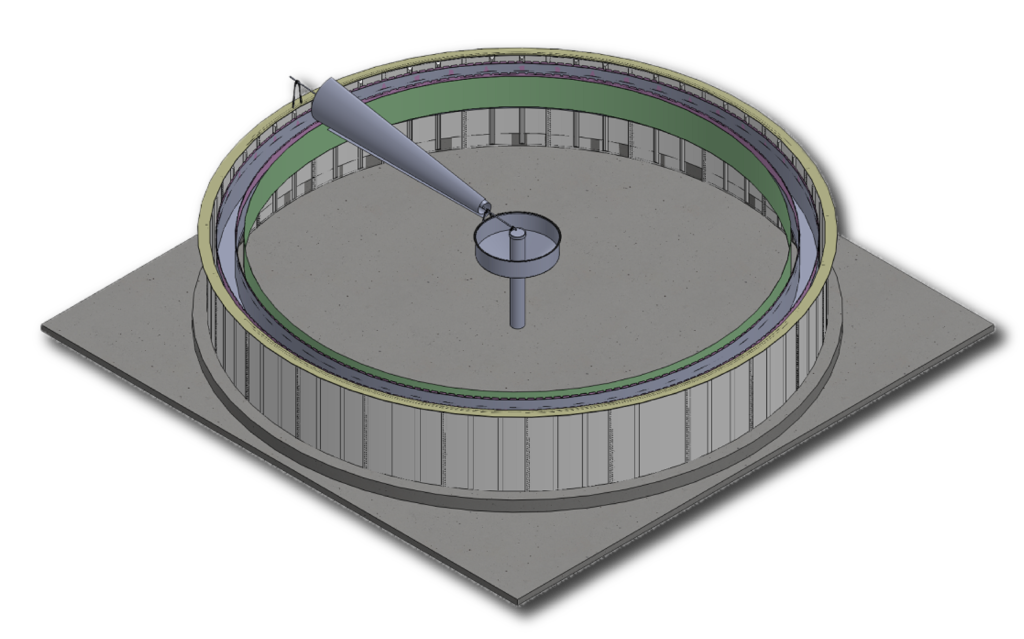

Toro Equipment ofrece tres tamaños de floculadores diseñados para los diferentes modelos de flotadores: FLH modelo estándar, FLH modelo superior y FLH modelo FRL.

Incluyen: Toma de inyección de reactivos, grifos de toma de muestra que permiten controlar la cantidad de químico inyectado, sustentación en PRFV y acero AISI 316.

Take a look at the product references and consult all the information about them